As the oil and gas industry continues to grow, companies are faced with the challenge of preserving equipment and materials from corrosion. Corrosion can cause damage to equipment, resulting in costly repairs and even shutdowns. To combat this issue, companies turn to VCI (volatile corrosion inhibitor) preservation products to provide protection against corrosion.

OneSource, in partnership with Daubert Cromwell, provides a range of VCI products specifically designed for the oil and gas industry. In this article, we will discuss the benefits and applications of each of these products.

Corrosion occurs when a material, usually a metal, undergoes chemical reactions with its environment. In the oil and gas industry, factors such as moisture, oxygen, and chemicals can accelerate the corrosion process, causing the deterioration of structures and equipment. Effective corrosion control is essential to minimize the adverse effects of corrosion on equipment, production, and safety.

Proud to partner with Daubert Cromwell. They offer many VCI (Volatile Corrosion Inhibitor) products to protect metal surfaces from corrosion. OneSource found various VCI Preservation products for application in preservation for the O&G industry.

Here is a description of the different VCI products from Daubert Cromwell that OneSource offers for the O&G industry:

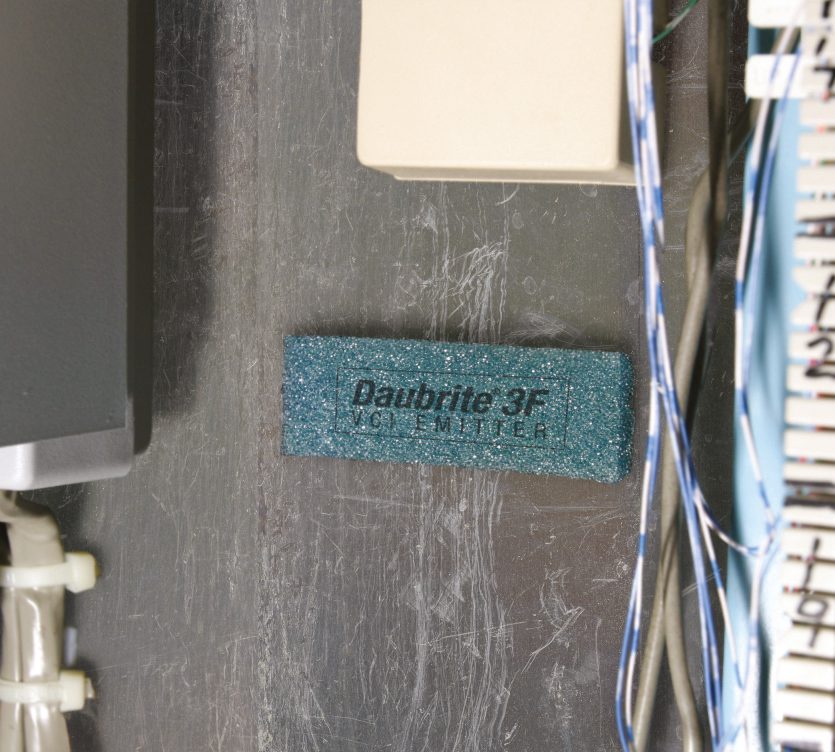

VCI Emitters are a type of VCI preservation product that releases a vapor into the air. This vapor protects metal surfaces from corrosion by forming a protective layer on the surface. VCI Emitters are ideal for protecting large, enclosed spaces like storage containers, tanks, and pipelines.

VCI Oil is a specially formulated oil that incorporates corrosion inhibitors. When applied to a metal surface, it forms a protective barrier that prevents corrosion.

Benefits of VCI Oil

Applications of VCI Oil

Water Soluble VCI is a type of VCI preservation product that is designed to be added to water-based systems. It protects metal surfaces from corrosion by forming a protective layer on the surface. Water Soluble VCI is ideal for use in cooling systems, water treatment plants, and other water-based applications.

VCI Powder is a dry powder that can be applied to metal surfaces to provide corrosion protection. The powder dissolves in moisture to create a protective layer on the surface. VCI Powder is ideal for protecting metal parts during storage or shipping.

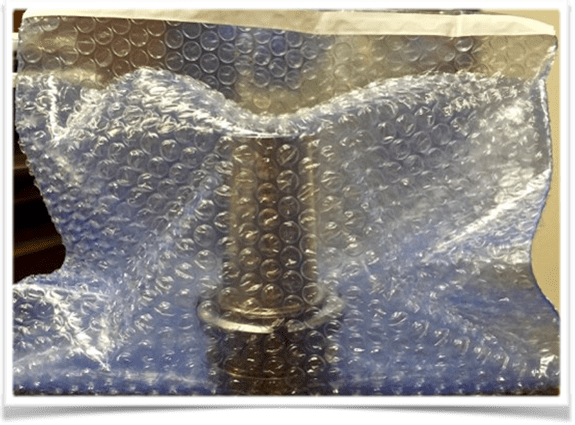

VCI Film is a type of VCI preservation product that is designed to be wrapped around metal parts to provide protection against corrosion. The film releases a vapor that forms a protective layer on the surface, preventing corrosion. VCI Film is ideal for use in the oil and gas industry for protecting metal parts during storage and shipping.

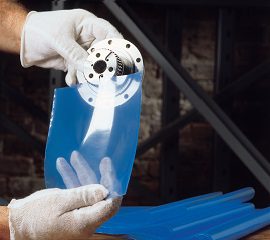

Corrosion preventive coatings are a type of wax that protects surfaces against corrosion. While they do not contain VCI, they are commonly used in conjunction with VCI products to provide additional protection against corrosion.

These coatings are available in a variety of forms, including liquid, aerosol, and paste. They can be applied to metal surfaces such as pipes, tanks, and machinery, as well as non-metal surfaces such as concrete and wood.

The benefits of corrosion preventive coatings include:

When used in conjunction with VCI products, corrosion preventive coatings can help provide long-lasting protection against corrosion and extend the life of equipment and infrastructure.

Grease is a type of lubricant that is used to reduce friction between moving parts. While it does not contain VCI, it is often used in the oil and gas industry to lubricate machinery and equipment.

The benefits of using grease in the oil and gas industry include:

When used in conjunction with VCI products, grease can help provide additional protection against corrosion and extend the life of machinery and equipment.

VCI preservation products offer an effective way to protect metal surfaces from corrosion in the oil and gas industry. By partnering with Daubert Cromwell, OneSource is able to provide a range of VCI products to meet the needs of our customers.

Whether you’re looking for VCI emitters, VCI oil, water-soluble VCI, VCI powder, VCI film, or corrosion preventive coatings, we have a product to meet your needs. By using VCI products in conjunction with corrosion preventive coatings and grease, you can help extend the life of your equipment and infrastructure and reduce maintenance costs over time.