Hot Oil Flushing: Optimizing System Integrity And Performance

Hot oil flushing circulates heated oil through infrastructure to eliminate accumulated contaminant buildup. This vital maintenance practice maximizes system integrity across oil and gas operations.

How It Works

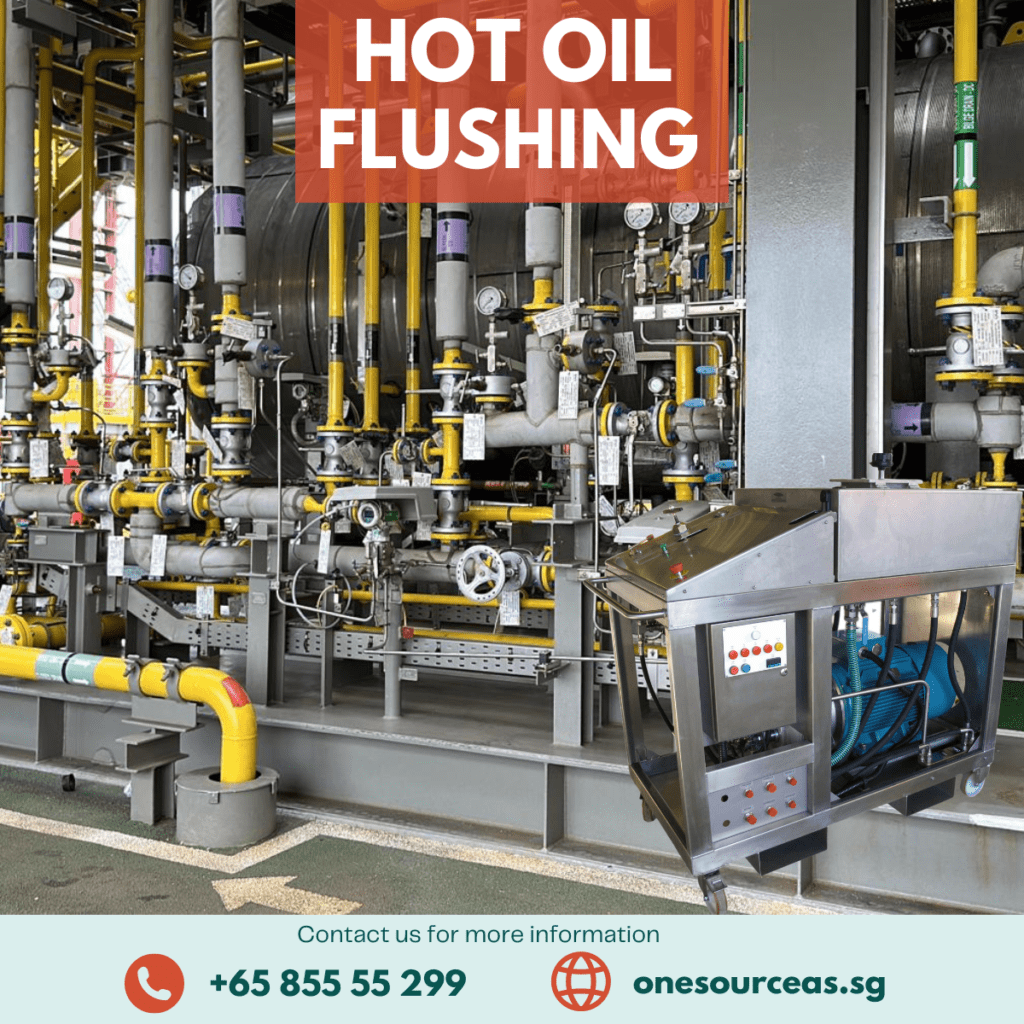

Hot Oil Flushing Pumps push hot oil at high velocities, leveraging temperature and flow to dissolve and extract entrenched sludge, rust and other debris. Custom filtration systems then remove particulates, restoring cleanliness.

The Benefits

Effective hot oil flushing:

Customized Flushing Services

OneSource engineers tailored hot oil flushing solutions based on:

This customization ensures optimal outcomes.

Reliable Project Execution

Choose OneSource for reliable hot oil flushing delivering cleaner, longer-lasting system functioning.

OneSource performs Hot Oil Flushing to clean and purify operational fluids in a hydraulic system by circulating hot oil through the system under high pressure. This is typically done during maintenance, repair work, or when the system is commissioned for the first time. Depending on the Client’s requirement, we can use either mineral-based or water-based oil as well as synthetic or bio-based oils.

OneSource has multidiscipline professionals and rental equipment available for the whole Asia region. Please do contact us at singapore@onesource.as for more information.